|

BACK TO #448

|

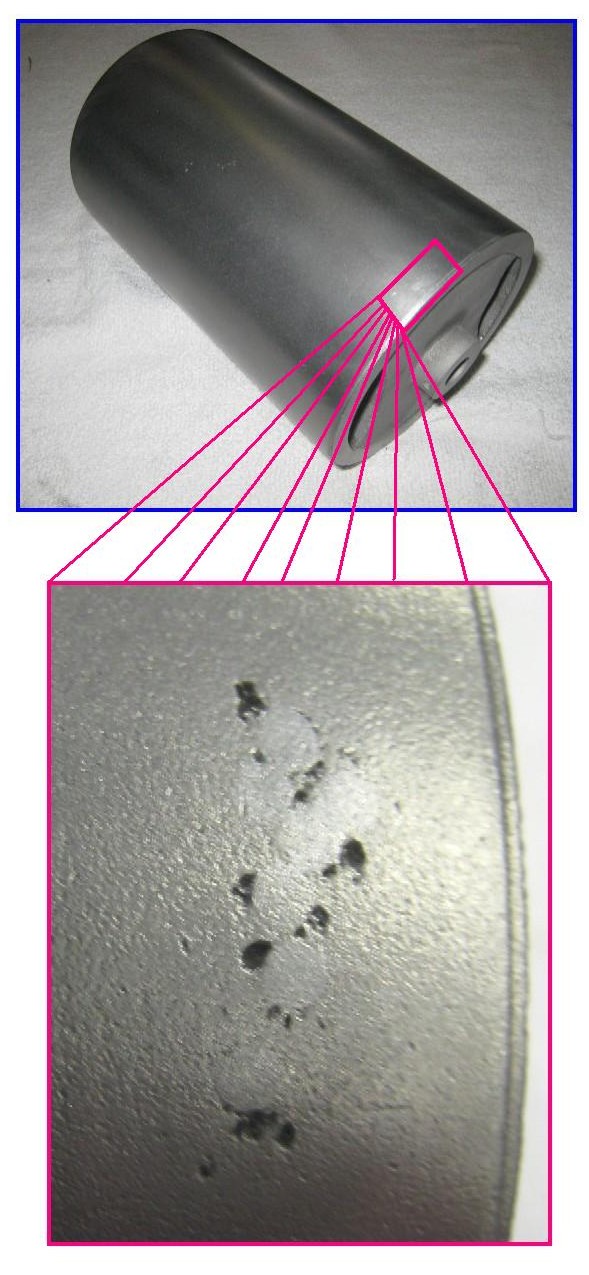

A couple items I’ve noticed during this restoration with factory repairs on them. Below you’ll see the auto inker roller. Once I got it cleaned up and polished I could see they had some issues with rough casting pits in it. Looking at this item it would be very hard to cast a hollow roller so if repairs could be made to save it from being recast they’d be money/time ahead. The repair would be made by drilling a small hole in the pit and then taking a round rod just a couple thousands larger and pressing it into the hole. During the turning/facing process of this item the repair would almost become unnoticeable when finished. If you look close at the enlarged picture you can see the small round steel rods in the cast iron. In the 1880’s welding repairs were not common……we were still in the blacksmith era. I have also found repairs like this in the ink disk, and platen faces. All these have one thing in common; they were bare metal from the factory and needed to be FLAT. .

|