|

BACK TO #448

|

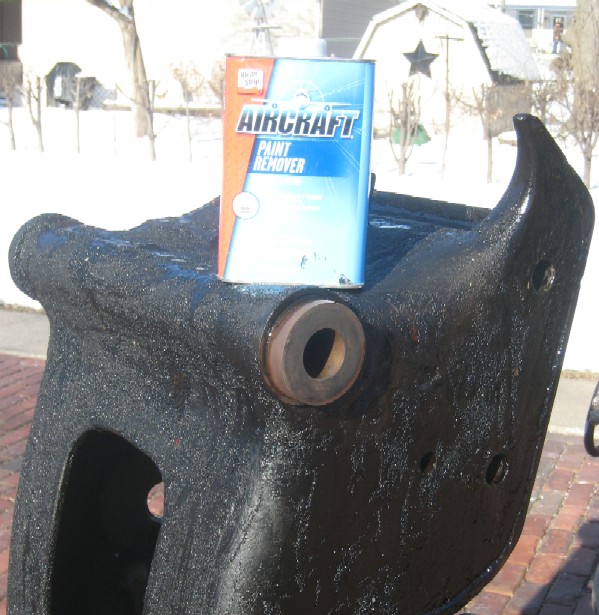

Before I moved the press outside into the cold I brushed a nice coat of "Aircraft" paint remover across the base. This helps reduce sandbasting time. The spots you see all wrinkled up in the picture just fly off when I hit that area with the blaster. Not only does it help in removing the paint, but it also softens up any caked on oil around the bushings. On this project it also soften up dried ink, and in some spots the ink was very thick!!! Surprise Surprise.

CAUTION: Before using paint remover like this please make sure you have plenty of ventilation!!! Be very careful where you use this. One like spec on your skin will burn!!! One like spec on ANY painted surface will damage or remove it!!

My normal sandblasting system is in a closet that you sit your hands into and look through a window. You don't get very dirty and normal street clothes can be wore. But since the base it to large the blaster had to be moved outside. With that comes proper sandblasting gear. Safety items shown below are a must. Eye protection, ear plugs, dust mask, face shield, gloves, and a stocking cap are required. Long sleeve shirt and pants too. All parts of your body need covered because sand will hit you somewhere and it HURTS when it hits.....and if it's the wrong spot you might get hurt requiring medical attention. Be safe, Cover it!!!!

After about 4 hours outside the base if finally blasted clean. A couple times I stopped and applied more paint remover to loosen ink and grease. I also got out the putty knife and pick and did lots of scraping in corners and edges. The base is ready for the next step!!!

|