|

BACK TO #448

|

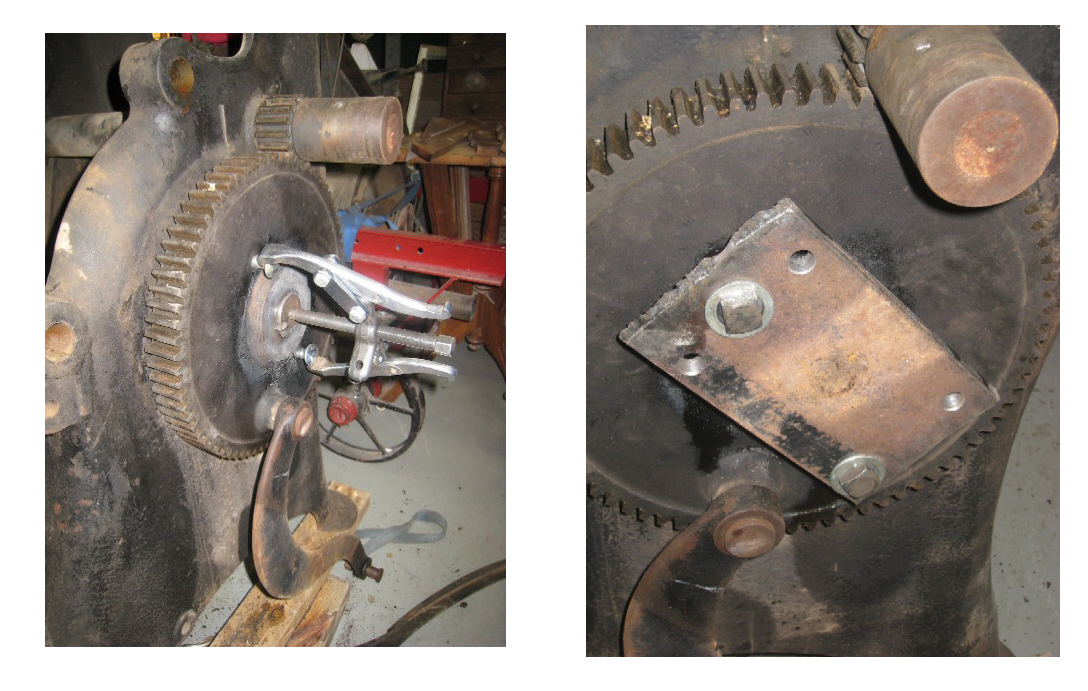

I first tried the quick and easy gear puller, what the heck it's gear so it's got to be the correct type puller. After putting about maximum pressure I could in it I gave up with this puller and when for something different. From LetPress I was told to try a harmonic balancer puller, which by chance I just don't happen to have. I ordered one up and a couple days later got it. When I got the puller ready to go onto the gear I noticed the puller would only got to 5 1/2" and not 6" like I needed. So back to the heavy scrap piece of snow plow blade that I use for stuff like this. I had to drill another hole in this harden steel, which is not easy to do. I installed my homemade puller and set ready to remove this main gear.

Again this type puller is great because you can put pressure on the gear (or whatever your pulling off) and then hit the center of the puller as hard as you want with a hammer to help loosen the two items that are stuck together. I tighten up the bolts and gave the puller a firm, but not hard hit in the center and POP. The sound rang through the press housing. I looked close and my gear moved about an 1/8". I tighten the bolts and hit it again...POP. SWEET!!!! I kept repeating this until I ran out of puller. I then loosen the puller back up and put a large nut over the shaft for a spacer and started again. When that nut ran out I put another one on it. After a short time the gear was successfully removed. The last picture shows the key laying in the shaft. It too like the flywheel key is straight not tapered. All keys I've found in #448 are straight keys, nothing is tapered.

|